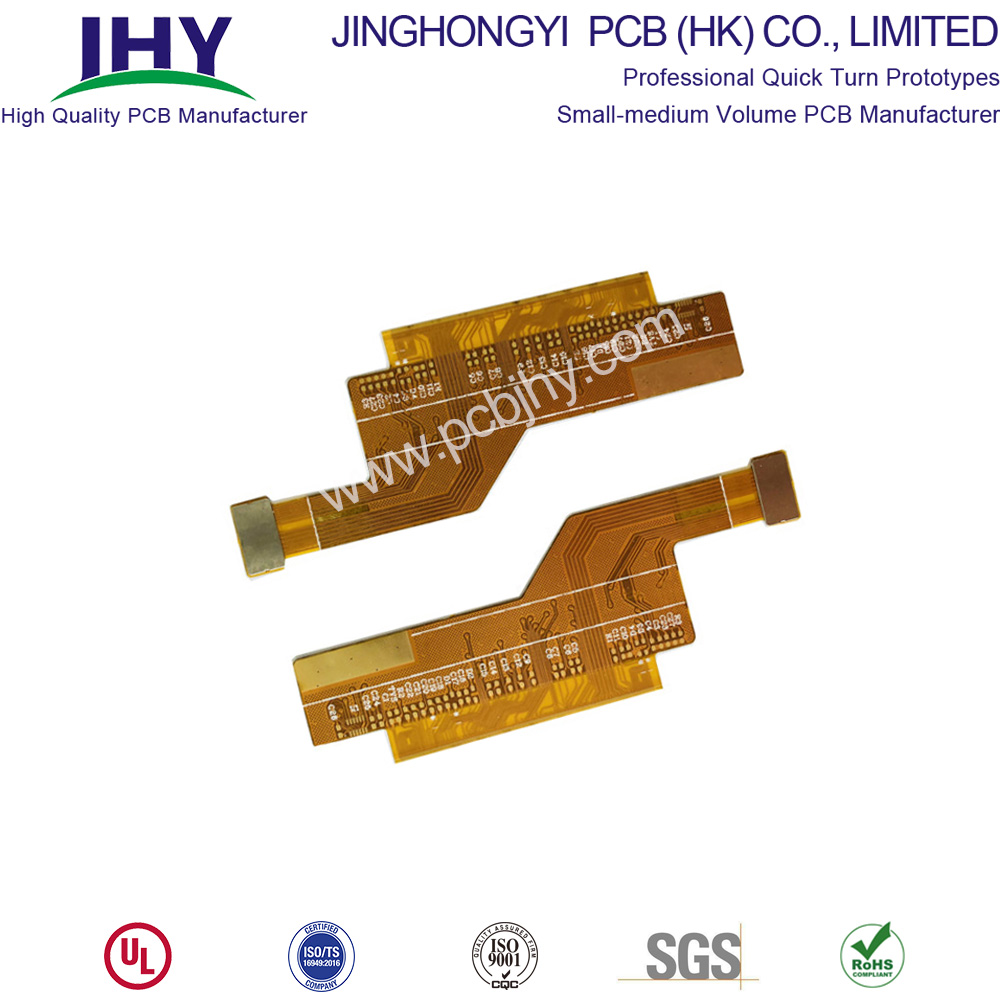

Quick Turn Prototype Flexible PCB Manufacturing FPC

Product Description

Prototype Flexible PCB Board

Prototype are the backbone for any flexible PCB project. Whether you are a PCB hobbyist or a high tech engineer working on a military application which requires a flex circuit, then a prototype flex circuit is needed to test your device to ensure the design will work and function correctly before production begins.

Get The Flexible Circuit Prototype Board You Need

we build every flexible circuit board custom to our customer's specifications.

Every online flexible circuit Board order goes through a design review in our engineering department to ensure the manufacturability of your flex PCB design and reliability of you gerber data.

Low Cost Prototype Flexible Circuit Boards

We offer low cost flexible circuit board prototypes that can be ordered online 24/7 at a variety of lead times. With no minimum order quantities, you can order your flexible PCB prototypes online and have them in as little as 7 days with our available quick turn flex PCB solutions. You will only have to pay for tooling once when moving your flex circuit design into production.

Flexible PCB Defined

A Flexible PCB or FPCB is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible coverlay. These flexible electronic assemblies may be fabricated using the same components used for rigid printed circuit boards, but allowing the board to conform to a desired shape (flex) during its application.

Flexible PCB / FPCB Applications

FPCBs are used widely in everyday technology and electronics in addition to high-end, complex completed components. A few of the most prominent examples of flexible circuits Board usage is in modern portable electronics, devices, hard disk drives and desktop printers.

Flexible circuits Board are also used extensively in Other applications and industries including:

- Communications

- Consumer Electronics

- Automotive

- Medical

- Industrial

- Aerospace

- Military

- Transportation

In transportation they are extensively used due to their improved resistance to vibrations and movement.

Prototype Flexible PCB Fanufacturer

Products & Services

- Quick Turn PCB

- Rigid PCB

- Flexible PCB

- Rigid-flex PCB

- Aluminum PCB

- PCB Stencil

- Multilayer PCB

Learn more about JHY PCB by exploring the manufacturing capability of Flexible PCB below. We can do more than you can imagine.

| Items | Manufacturing Capability | |

| PCB Layers | 1 - 8layers | |

| Laminate | DuPont PI, Shengyi PI | |

| Maximum PCB Size(Length x Width) | Single Sided PCB | 480*4000mm |

| Double Sided PCB | 480*1800mm | |

| Multilayers | 236*600mm | |

| Minimum Board Thickness | Single Sided PCB | 0.05mm+/-0.02mm |

| Double Sided PCB | 0.08mm+/-0.02mm | |

| Multilayers | As per Gerber | |

| Finished Board Thickness | 1-6L | 0.05mm-0.6mm |

| 8L | 1.6mm | |

| Min Tracing/Spacing | Copper Thickness 1/3 oz: | 0.076mm/0.076mm (1-6L) |

| 0.05mm/0.05mm (8L) | ||

| Copper Thickness 1/2 oz: | 0.076mm/0.076mm (1-6L) | |

| 0.06mm/0.06mm (8L) | ||

| Copper Thickness 1oz: | 0.1mm/0.1mm (1-6L) | |

| 0.065mm/0.065mm (8L) | ||

| Min. Annular Ring | 4mil | |

| Minimum Hole Size | 1-6L | 0.2mm(8mil) (CNC) |

| 8L | 0.15mm(CNC) | |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow | |

| Solder-stop coating---Coverlay | PI and PET film | |

| Silkscreen Color | White, Black, Yellow | |

| Surface Finish | OSP | |

| e HASL | ||

| ENIG(Electroless NickLead-Freeion Gold) | Ni thickness:2-6um | |

| Au thickness:0.025-0.05um | ||

| Flash Gold | Ni thickness:2-8um | |

| Au thickness:0.025-0.15um | ||

| Immersion Tin | Tin thickness:0.5-1um | |

| PlatingTin | Tin thickness:1-10um | |

| Laser cuPunching | ||

| Special technologies | Peelable solder mask | |

| Gold fingers | ||

| Stiffener (only for PI/FR4 substrate) | ||

| Impedance Control+/-10% | ||

| Rigid Flex PCB | ||

PCB Shipment

JHY PCB offers flexible shipping methods for our customers, you may choose from one of the methods below.

Shipping Process

After production and testing, your PCB orders will be sent to our shipping department. As the quick turn PCB manufacturer, JHY PCB shipping department will ship your PCB quickly without any pending.

JHY PCB 's Packing Way

- Use one professional PCB vacuum bag, with desiccant inside. Vacuum compressed totally.

- Paste label and RoHs mark. Use second vacuum bag to protect boards again, vacuum compressed, make sure no exception.

- Microsection report and Tin testing board are put together with PCB in cartons.COC (Certificate of Conformity) will be sent to customer by email in PDF.

- Several layers of thick EPE(Expand aple poly ephylene) are filled fully in gaps between PCBs and cartons. Thickness of 1 layer EPE is 10mm.

- Neutral Packing is adopted if no special requirements. Strong and thick cartons(Thickness:10mm,7 layers). Different sizes of cartons are designed to meet demand of different PCB size. All package are within weight limit of cartons. For mass production order, no exceed 21kg per carton normally.

- All cartons sealed with strong adhesive tape should be sealed twice so as to make them more durable.

- Solid PP/PET strapping is used outside of cartons.

- Shipping mark, fragile mark and postcode label are all pasted clearly.

How to ship your PCB?

- Firstly, JHY PCB shipping department will print order address and invoice.

- Secondly, JHY PCB will set the shipment information on the Logistics company website.

- Thirdly, the Logistics company staff will collect the package from JHY PCB and ship it to you.

With the purpose of better customer service and meeting the customer demand, JHY PCB provides following shipping methods.

JHY PCB is experienced in exporting. For PCB Prototype and small-medium volume PCB order, we have stable and long-term good relationship with forwarder, such as international express company DHL, FedEx, TNT, UPS. For mass production order, we have famous and reliable shipping company for support.

FAQ

Q1: What is your minimum order quantity?

A: Our MOQ is 1 PCS.

Q2: Do you accept PCB design with different boards on one panel?

A: Of course, we can do different boards on the same panel.

Q3. Are my Gerber Files safe?

A: We protect the intellectual property for customers in the whole process. All documents from customers are never shared with any third parties.

Q4: What is needed for quotation?

A: Quantity, PCB Gerber file, Technical requirements(material, board thickness, surface finish, copper thickness,solder mask color, silkscreen color, ...)

Q5. How to quote shipping cost?

A: The shipping cost is determined by the shipment way(forwarder name, delivery days), destination, weight&dimension of packages. If you use your own forwarder, please inform us.

Product Categories : Flexible PCB